History

Brianza Plastica is born

Brianza Plastica was founded in 1962 to produce fiberglass laminates in sheets and rolls for commercial and industrial applications. Over the years, the production was expanded with sites in Italy and Europe, introducing new products able to meet the most varied building needs.

Inauguration of Plasti-Bat

French subsidiary of the Brianza Plastica Group, Plasti-Bat was born in 1976 in the Lyon region, specializing itself in light roofing, building insulation systems and synthetic glass for professionals and large DIY stores.

The Isotec® system

In the Eighties, the Company entered the field of thermal insulation for roofs in the residential and industrial sectors. The Isotec® system was born in 1984, an innovative thermal insulating under-tile panel in polyurethane.

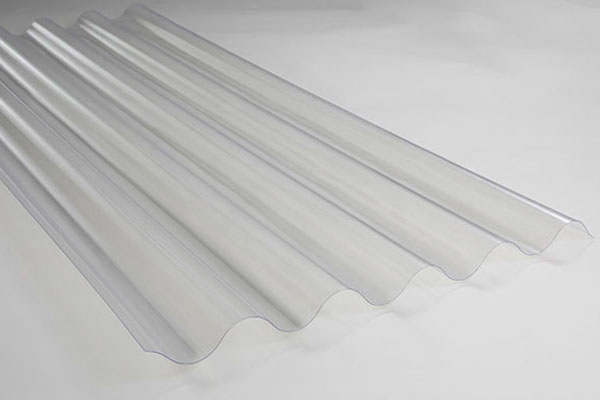

Fiberglass laminates growth

Over the years, the Company continued in the production and constant research and implementation of fiberglass products, expanding its range and finishes of flat and curved sheets and rolls, wavy, corrugated or smooth, opaque or translucent, for applications in a variety of different fields such as agriculture, breeding, commercial and industrial applications, as well as commercial (trucks, buses) and recreational vehicles (campers and caravans).

New production sites

The acquisition of the two production sites of Rovigo and Ostellato - respectively in 2006 and 2008 - to produce Elycold® laminates and the inauguration in 2009 of a new production line in the Carate Brianza site dedicated to Elyplan® continuous hot-laminated products, has made Brianza Plastica one of the most important players in the global market of fiberglass laminates, with an extremely flexible production capacity.

Brianza USA Corporation

The new logistics-commercial headquarter of Brianza USA Corporation in Elkhart, Indiana was founded in 2014 to serve the US market and to strengthen its commercial presence in the american territory.

Second production site in Rovigo

In 2016 the opening of a new production site in Rovigo and a new continuous production line in Carate Brianza were inaugurated.

New chemical lab

At the beginning of 2019, the new chemical laboratory almost tripled the previous surface area; it’s equipped with the most advanced instruments to support the production processes of composite laminates and insulating products.

Launch of Elysol®

In 2021, at its production site in Ferrandina (MT), Brianza Plastica started producing Elysol® compact polycarbonate sheets.

Sites & Plants

The Brianza Plastica Group

The Brianza Plastica Group is made up of three Companies that contribute to the study, production and supply of high quality materials and products, thus making the Brianza Plastica Group a leader in the field of fibreglass laminates and industrial and civil insulation. The Company counts 5 production plants, all based in Italy.

Brianza Group

Companies

Production

Plants

Over

Years

ENVIRONMENTAL SUSTAINABILITY

ENVIRONMENTAL SUSTAINABILITY

Brianza Plastica in 2020 introduced the UNI EN ISO 14006 guidelines on eco design, intended to point maximum attention to not only to the impact of its production processes on the environment, but above all, on the extreme importance of analysing the entire life cycle of its products, from design to end-of-life management.

Brianza Plastica has always stood out for its focus on safety, the environment and people, operating in full compliance with the current laws on environmental hygiene. With this in mind, the Company has equipped its production sites with powerful suction systems that purify the internal environmental by conveying the solvents, generated during the production process, to highly advanced abatement systems.

In 2020, the Company entered into a partnership with a major waste management facility aimed at “ennobling” the end-of-life of its waste and production residues in fibreglass. Thanks to this collaboration, almost all of the waste coming from the production processes is now destined for use in cement and steelworks in the form of RDF (refuse derived fuel).